Heater Power Distribution

Heater Power Distribution Optimization

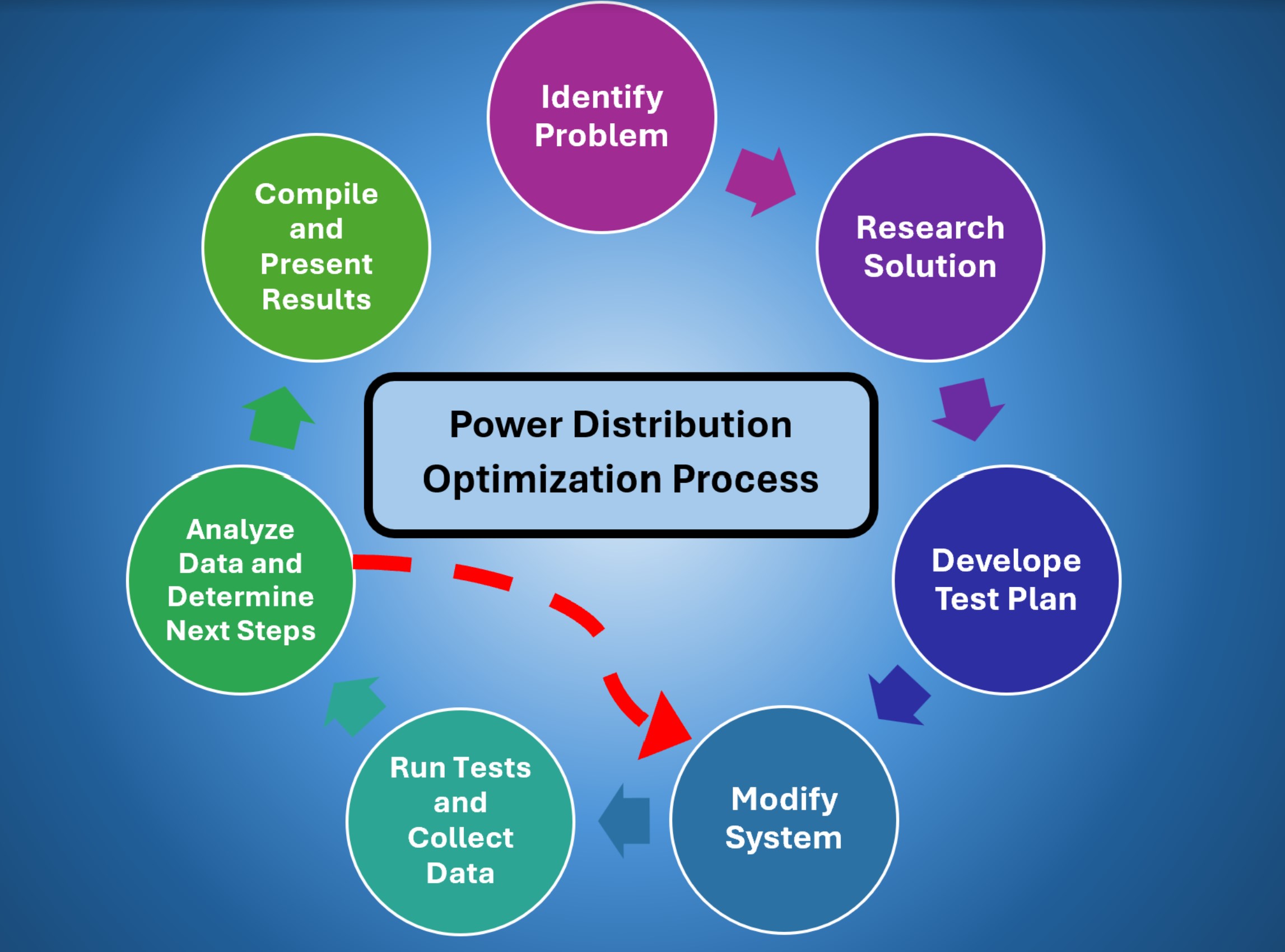

This project involved designing and implementing an optimized power distribution strategy for an oven with multiple heater circuits. The goal was to enhance thermal efficiency and achieve precise temperature control by continuously adjusting power distribution and cycling patterns across the heater banks.

Project Overview:

• Heater Power Optimization: Developed an advanced power distribution system across three independent heater circuits to enhance overall cooking performance and energy efficiency

• Temperature Uniformity: Improved temperature consistency throughout the oven cavity by dynamically adjusting heater cycling patterns to maintain even heat distribution

• Collaborative Controls Development: Worked closely with the control systems team to design, implement, and validate new algorithms, ensuring precise data collection and control for optimal heater performance across all cooking functions

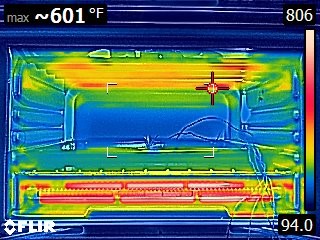

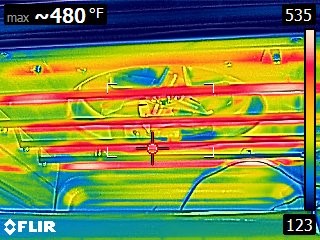

Used FLIR thermal imaging to analyze temperature distribution and verify that internal components remain within safe operational limits, ensuring component longevity and optimal thermal management

Electrical Engineering Development:

• Custom Test Setup: Designed and wired a custom test setup using four variacs to control voltage for three heater banks and the motor, creating a safe and efficient wiring schematic for all components

• Thermostat Control: Programmed and implemented an external digital thermostat to monitor and control power cycling for each heater circuit, optimizing heating performance

• Power Management: Managed overall system power usage, manually setting variac wattage to maximize performance while ensuring power draw stayed within the 1800W outlet limit

This diagram illustrates the iterative engineering process applied to optimize the oven's power distribution system, from identifying performance issues to developing solutions, testing modifications, and analyzing results for continuous improvement.

Testing and Data Collection:

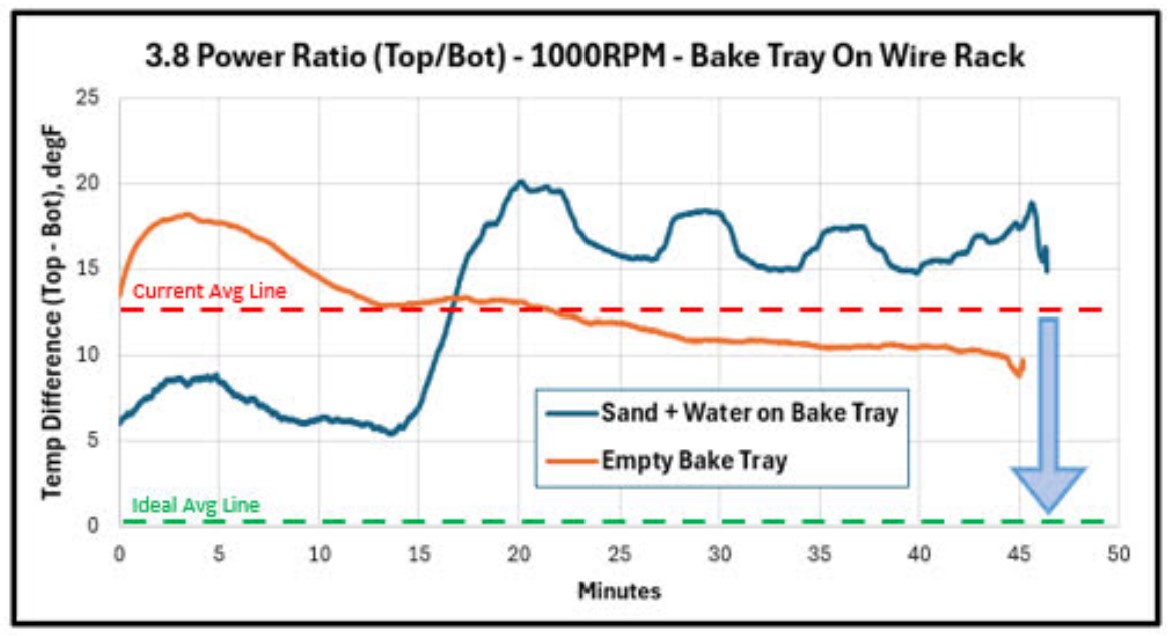

• Iterative Testing: Conducted iterative tests at a fixed total power input, adjusting power ratios between heater banks to identify optimal distributions

• Control Flow Optimization: Generated data that informed control flow development, providing key insights into power cycling and heater management

• Data Analysis: Analyzed test results to evaluate effectiveness, tracking normalized temperature differences across various power ratios

Test Setup: External wiring of heaters controlled via individual variacs to optimize power distribution, with the DAQ system tracking temperatures throughout the test.